Please build robots to automate plant tissue culture

Bottlenecks, ancient robots, and a few companies actually doing this

A technology to grow thousands of genetically identical plants in a few squared meters, virtually eliminating the risk of pest infections at the earliest growth stages and the use of pesticides or fertilizers in young plants, bypassing the complications of germinating a new variety, and sometimes even seasonality too. It’s been here for over sixty years, it’s grown to serve a >380-million-dollar market, and it’s called plant tissue culture.

Despite such attributes, the largest cost driver in plant tissue culture is still labor. While mammalian biotech is increasingly automated with all kinds of liquid and plate handling devices and there are multiple efforts to automate agriculture in the fields, currently there are only handful of companies in the world that build robotic systems to make the tedious process of industrial plant micropropagation (aka tissue culture) more time efficient and cost effective.

The number of plant molecular farming, cellular agriculture, gene editing, companies is increasing and plant tissue culture is an infrastructural base for them to grow and develop their products. Robotic arms and bioreactors made specifically for plant micropropagation could significantly reduce costs of this technology. First for big companies, soon for the smaller businesses, nature preservation NGOs, and the indie planters who will grow the plants of our dreams.

This is an exploratory article. Choose your own adventure:

“Spoiler: bottlenecks ahead” is a primer on plant tissue culture and some cost analyses

“Back to the future” is a collection of attempts to automate plant tissue culture in before the 2000s

“C3-PO: Your favorite Cyborg Plant Organizer” is a short list and description of current companies building robots to automate plant tissue culture

“Think outside the jar” is a list and brief description of complementary technologies helping at different stages of the micropropagation process

Spoiler: bottlenecks ahead

Broadly speaking, thousands of seeds may be sold for the same price of a single or a few in-vitro plants. It’s not prohibitive for the value propositions mentioned above, added to the ability to grow thousands of plants from a single tissue cut in a super small portion of land. However, there are a few complications…

First, anyone who’s been there and done that knows how tedious and labor-intensive it is to make plants in jars. The damn green things are so delicate and different from each other that it requires the average human months of training to get decently fast and dexterous at this job.

Those humans’ salaries can make up for more than half of operation costs. In high income countries, this is the largest cost driver after electricity. In lower income countries, electricity and reagents tend to be the largest cost drivers — more material for the next season of the Decentralization of Biotech Innovation.

For reference, a study done in India estimated a cost of $0.49 USD per plant, with materials as the largest portion, while another study done in Taiwan got $0.28 USD per plant having direct skilled labor as their largest cost, by far. Does anyone have any data on European countries?

Out of the ~4 stages in the plant tissue culture process, multiplication of the tissues and acclimatization of the final plants are the most labor intensive ones. How labor intensive multiplication is depends on the company’s tissue culture strategy, which means, what type of tissue they want to culture in order to get to a final plant with roots and shoots.

While an embryo should not be cut, microshoots are actually multiplicated by taking cuts from the initial culture and distributing them in other jars. Both routes can be either direct from the explant, or indirectly derived from plant “stem cells” called callus that do require cutting for long term maintenance as they oxidize over time.

A bioreactor may be used in any of these cases to better control the growing conditions and provide a larger space for explants to grow without the need for cutting or the use of gelling agents. Another very important advantage of bioreactors (and other automation systems that will be discussed in the next section) is that they significantly reduce the risk of fungal contamination that might otherwise occur even in the best trained hands.

While some companies may export thousands of plants in their jars across the world, which has its obvious advantages, others may go through final tedious stretch of transplanting each one of them from their comfy jars back into soil. Unless I lack creativity, there doesn’t seem to be anything that currently saves companies from this hurdle. Or is there???

Back to the future

TOSHIBA was among the first companies in the world to showcase their automated system for masspropagation in the 90s. It consisted of two robots: one would measure the plantlet shapes through laser beams and decide the cutting positions, then the other would grip the stem of the plantlet, cut it between the nodes, transplant the cut-out segment into the other tray, and repeat.

They claimed the robot was able to cut each plant segment in 5 seconds which, according to personal experience, sounds decently good. A human who knows what they’re doing might take less than 3 seconds per cut but, as we will see throughout this exploration, cutting is just one operation. To guide ourselves in the following examples, another metric is a maximum of 2,500 plants transplanted per human per day.

At that time, industrial robots used to cost around $100,000 USD. Only the combination of the demand from the automotive industry1, Moore’s law, and advancements in software and materials science would bring it down >10x by today. All this time, only industries with a larger demand like the automative and now pharma could provide a quicker ROI. Is now plants’ turn?

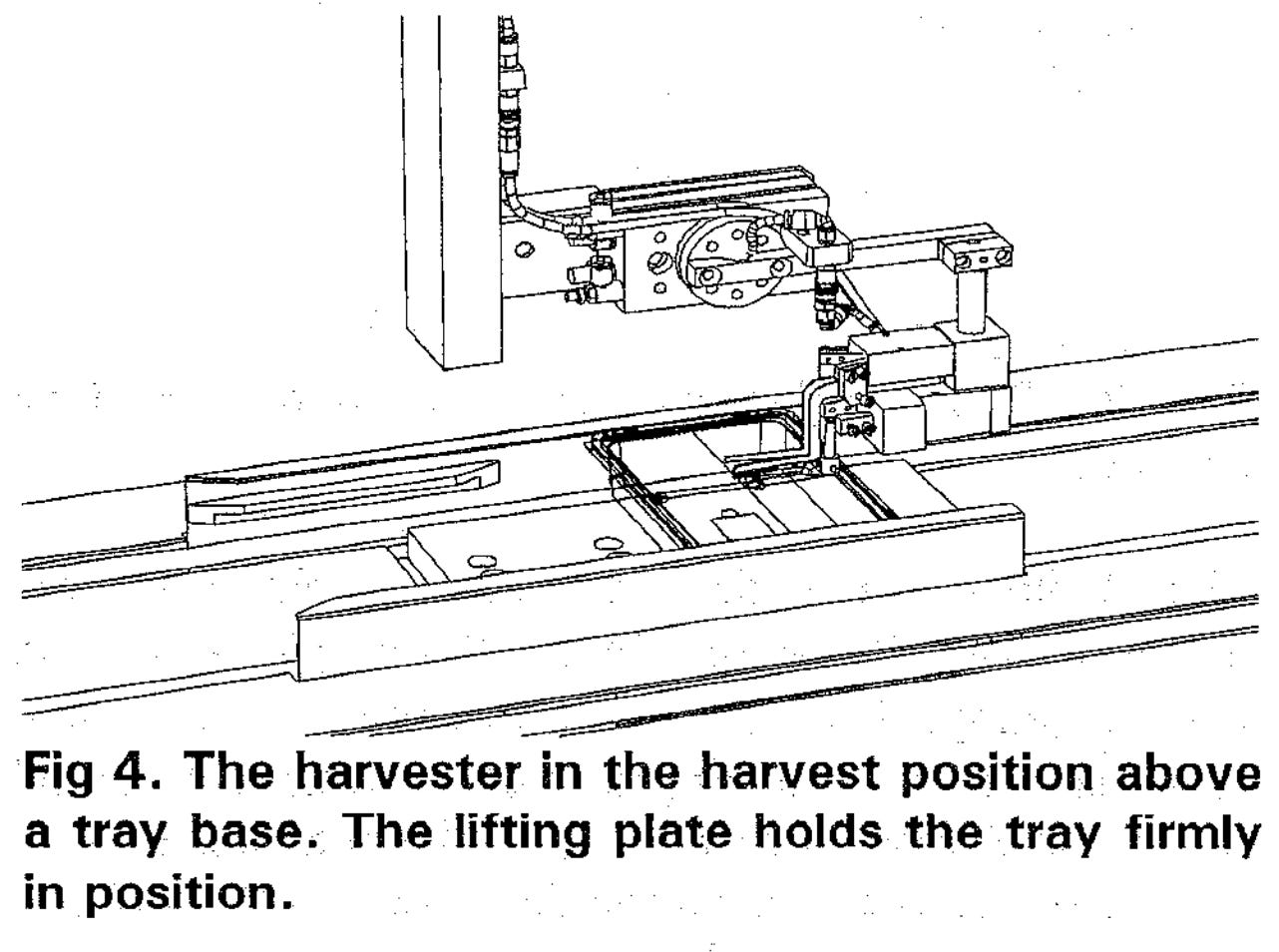

Another commendable attempt built by the Australian company ForBio Robotics was the Vitron TM 501, a tissue culture robot that could harvest a ~6cm tree plant from a tray, cut it into a smaller viable explants and plant these into trays with growth medium.

Tissue culture allowed them to look at genetic markers to know how tall each tree would grow when it’s only 3 cm tall instead of waiting 20 years, and select for a pool of those that would grow about the same size. They were also able to sterilize the trees to control the spread of any genetic modifications they made and concentrate energy into growth as opposed to reproduction. Still, not the right timing yet.

Lastly, NASA’s Jet Propulsion Lab also developed a similar system. The following is a short clip out of a full 5-minute procedure to place 2 plants in that agar plate. If it’s true TOSHIBA could do that in 15 seconds, 10 years earlier, I understand why US taxpayers might be dissatisfied (bad joke?). Anyway, NASA’s “micro” propagation resembles spinach and jelly than tissue culture.

C3-PO: Your favorite Cyborg Plant Organizer

“A third hand” might be the best way to describe SmartClone, the system demoed in 2020 by the Australian company NuPlant. Their innovation doesn’t end at robotics but using special squared culture media trays with little cuvettes inside them for each plantlet. This not only means more plants per squared centimeter but an easier time for the robot to pass them to the technician who cuts them. Together, they can transplant and cut each plantlet in about 5 seconds — a record?

Now, the system that caught my attention first and foremost was The Tissue Culture Planter unveiled by the horticultural producer ISO in collaboration with the experts in agriculture automation, Viscon Group, in 2023. Though the Planter doesn’t cut, it can transplant plantlets from a tray to a plate with new media using a combination of a delicate grip and forceps and computer vision software that keeps track of each individual tissue inside a completely sterile cabinet.

Viscon’s edge is to have been in the business of optimizing and automating all kinds of operations in crop and animal agriculture, including greenhouse production, vertical farming, warehousing, chicken hatcheries, and insect farming, since 1927. In the last few years, they’ve delivered 25 ready-made tissue culture labs around the world, including a large one in China that can produce 85 million blueberry plants annually.

Think outside the jar

A complex and labor intensive production line contains many individual hanging fruits to pick from before building or buying a Tesla Optimus that does it all. There’s cutting, mixing, pouring, cleaning, sterilizing, labeling. Since the easiest (temperature, light, and humidity control) has already been picked by quite many folks, we can look at the others.

One of the first steps in tissue culture is so boring that unlucky undergrads starting out in academic labs get to do it for free: preparing growth media. Microbiologists have autoclaves that hand them in ready-to-use Petri dishes with fresh media, but those aren’t made for the bulkier plant tissue culture jars.

Hence, RAYPA’s AE-MP prepares and sterilizes culture media for microbiology and plant tissue culture. It would be great to see it integrating with a system for automatic pouring into thousands of jars.

Once the undergrad has learned how to prepare growth media, they can go ahead and chop little green things using forceps and a scalpel which they need to sterilize using a flame and ethanol, carefully so they don’t cut themselves or burn the whole place down in the process. You can imagine how much time is lost between each cutting, not to mention how you can burn your explants if you’re not careful.

Enter plant lasers, one more elegant innovation of the past. A CO2 laser can cut 25 potato plantlets in less than 9 seconds and result in superior growth parameters compared to mechanical cutting. Just as robots, lasers have become several orders of magnitude cheaper per watt in the last 20 years but I’m not sure that even with great computer vision it would be worth the investment unless it’s seamlessly integrated with something like the Planter.

In between the media and the cutting lies the. No, we don’t talk about j@r$. We think outside of them to facilitate automation and save costs by packing more plants per cm2. Actually, Nic-In found out that you can fit 30% more plants in the same space simply by switching to rectangular containers.

Before we get to them, Growcoon is a little nest-shaped material where plantlets grow to be easily handled by a robotic arm without damage. As roots don’t grow as strong in-vitro than in-vivo, this device helps keep them safe before and as they go back to soil. I only wonder how many other seemingly little innovations might end up making a noticeable difference, especially together with automation…

Of course none of this matters, for those who actually want to truly automate the multiplication stage and significantly increase their yields will not be transplanting tissues across squared jars using robotic arms. They’ll be using squared (joke) bioreactors that can grow up to 100,000 plants per cubic meter, cut down labour cost by 75% in a fully automated model, and even eliminate the need for gelling agents!

Plant bioreactors can work so that plants are either immersed partially (through gases or turning), or submerged continuously (like for embryogenesis) which are mechanically agitated or air-driven.

The reality for low to middle scale production facilities in low income countries is that “any vessel” very often means using plastic bottles or even plastic bags that might look rather improvised and whose design is questionable especially regarding sterility. Are they optimal or is there a market need for bioreactors specifically designed for plant micropropagation? Another topic to the list of things I haven’t written about.

For the last stage of tissue culture (also left to the undergrads), the Australian company Nic-In has developed a transplanter that can do 14,000-15,000 plants per hour or the same work that would take 30 people per day. They take the whole agar block and put it in the substrate, which apparently won’t lead to contamination if you use their “Jungle Juice” of fungi that will keep other fungi away from your plantlet. Yes, you need to apply that to your agar plates somehow before transplanting.

Last but not least and encompassing every stage of the process is, quite surprisingly 🙄, some form of Artificial Intelligence. In the last few years we’ve been feeding AI with lots of image data from the fields. Today it’s interesting to see machine learning models that predict which tissues will germinate and which ones won’t, based on tissue culture image data. However, my eyes look towards a future where we feed AI with omics data, especially for GM😍s.

So, will you build the robots?

Regardless of your chosen tissue culture strategy, you will need to do cuttings of explants, media preparation, transplanting, and other repetitive and manual work. So, after this exploration, I do think there’s an unmet need for reasonably priced automation systems that optimize large scale tissue culture to drastically increase companies’ productivity.

Did I miss anything? Do you build robots and want to help grow plants that save the world? Do you grow plants that could save the world and resonate with this piece or disagree with something in it? Have a friend who would answer yes to either of these questions? As the YouTubers would say: comment, share, like, subscribe, shoot me a message, or all of the above.

Similar to

though, I’m intrigued by how Tesla’s robots (not the Optimus) look about the same as 70s robots. Why?

I really enjoyed this! I'm sure you've seen ARIA's recent thesis on programmable plants. https://www.aria.org.uk/wp-content/uploads/2024/02/ARIA-Programmable-Plants-v1.pdf They also acknowledge that plant tissue culture is a major bottleneck and given that they have £62.4m of funding for the programmable plants programme, I'm hoping we'll see some progress here. However, the funding will be spread out between only 9 "creator teams" so maybe we'll actually see progress from a more decentralized effort to address plant tissue culture.

This feels quite serendipitous, as I've actively been thinking about what it could look like to create a climate-focused community biology lab where one of the focus areas could be experimenting with ideas to automate the tissue culture process. I'd love your feedback, thoughts, and ideas! Or if you want to get involved, let me know! We need more people, whether trained scientists or enthusiastic amateurs, working on plants! :) https://jasandolive.substack.com/p/climate-community-biolab